“It is one of the rare inventions, where genius seems to have worked out for itself an independent field of action, and the benefits flowing from which are destined to be known and felt throughout the civilized world.”

Truer words were never spoken. This reference was to one of the first steam shovels, newly invented by William S. Otis, then at work on the Schenectady and Troy Railroad where (as the writer said)

“….it continues to excite a lively interest among citizens, thousands of whom have been prompted by curiosity to pay it a visit.”

Truer words were never spoken. This reference was to one of the first steam shovels, newly invented by William S. Otis, then at work on the Schenectady and Troy Railroad where (as the writer said)

“….it continues to excite a lively interest among citizens, thousands of whom have been prompted by curiosity to pay it a visit.”

As you can well imagine, seeing the first steam powered earth mover would have been a very big deal. It actually frightened many people who saw it in action for the first time.

At least two descendents of John Otis, who emigrated from England in 1631, and settled at Hingham, Massachusetts, were destined to make significant inventions, although history books only give due acknowledgment to the one associated with the creation of the passenger lifts.

William S. Otis, however, born in 1813 as the son of the Postmaster at Pelham, Massachusetts, is no less worthy of fame. Williams’ family moved in either 1828 or 1829 to Philadelphia, Pennsylvania, where in 1833 he joined the contracting firm of Carmichael & Fairbanks of which the senior partner, Danielle Carmichael, was his brother-in-law and by the following year he was himself a partner.

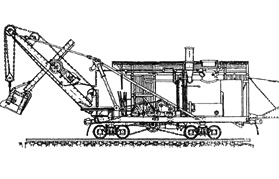

When Carmichael, Fairbanks and Otis had a contract to work on the construction of the Boston and Providence Railroad (later the New York, New Haven and Hartford) in 1835, William Otis made his temporary home at Canton, Massachusetts. Here, not only did he meet and marry a local girl, but also – with the help of a local man, Charles Howe French, recently out of apprenticeship to a millwright – he designed and built the prototype of the world’s first successful, powered, dry land excavator. This, built in a machine shop near the Massapoag Brook, was probably based on the quarry derrick principle and is believed to have had a mast supported by cables, a luffing-type dipper arm and bucket hinged to a boom, a double drum hoisting engine, and boom swing achieved by men at the sides pulling on ropes. The machine was clearly not easily moved as the derrick and excavating equipment were not fixed to a readily mobile frame also carrying the engine.

This Canton-built prototype was later used by Charles French on construction of the Norwich and Worchester railroad; and was possibly the same machine, incorporated into a dredge designed by Hosea T. Stock, which Charles French and Daniel Carmichael operated as contractors widening the Welland Canal, Ontario, in the 1840s and 1850s.

William Otis returned to Philadelphia in 1836, intent on building an improved version of his excavator himself with parts made by local machine shops. In the event he entrusted the complete erection of seven machines to Garrett and Eastwick, builders are locomotives and stationary engines, with premises on 12th St. The first Philadelphia built Otis shovel was produced in 1837 and by the time the second emerged the firm’s name had become Eastwick and Harrison; Joseph Harrison Junior, the skilled foreman who is likely to have contributed much to perfecting mechanical details of the shovel’s design, had bought out Garrett’s interest.

Although William Otis had filed his original patent application on the 15th of June 1836, a fire in the patent office destroyed this and a second application dated 27th of October 1836 was allowed on 24th of February 1839 and numbered as 1089. In this new restored patent application for a ‘Crane excavator for excavating and removing earth’ the inventor did not make any claim to the mere using other scraper by means of a train, this having been done before.

The Otis shovel was the first excavator to break and remove material by employing a single bucket with power thrust for adjusting the radius of a cut above, and to a limited extent below, ground-level. It was self-propelled and exhibited the three basic digging features still present in excavators equipped as a shovels: these are hoist, crowd (or racking) and slew (or swing).

Philadelphia built Otis shovels had a wide timber frame supported on cast iron traveling wheels which ran on temporary rails; the frame carried the boiler, engine and gears as well as all the excavating equipment and had projections with screw jacks for added stability when working. A triangular timber boom was supported by a pivoted, tubular, cast iron center post with a semicircular slewing ring attached to its top.

Power for hoisting was taken by chain from a grooved drum, through the inside of the center post to pulleys on the post and boom and then down to the bucket (scraper). A shaft with bevel wheels at each end carried a power down from the post pulley to another shaft between the main lower braces of the boom which, with its appendages, was the key feature of the Otis shovel. A drum fitted to this shaft carry chains in reversed direction attached to opposite ends of the dipper arm: this device provided controlled thrust with the capability of absorbing shocks, to the arm and its bucket of around 1 1/4 yd.³ capacity.

Up to 180° of slew was achieved by means of a chain from another drum taken round the sloughing ring. At the rear of the machine, a vertical wood-burning boiler provided low-pressure steam to a single cylinder vertical engine, with an approximate a bore of 23 cm (9 inches) diameter and 30 cm (1 foot) stroke, fitted at its front; this resulted in units ranging from about 8 to 20 hp. Contemporary accounts indicate that an Otis shovel could do the work of between 60 and 120 men: it’s estimated output was around 100 yd.³ of material per hour.

Of the seven Philadelphia-built shovels only two remained in North America. There are suggestions that the first work undertaken by one of these was on the Baltimore and Ohio Railroad in Maryland, but the first incontrovertible use of a powered excavator was in 1838 at Springfield, Massachusetts when Carmichael, Fairbanks and Otis were building a link of the Western Railroad (later Boston and Albany) to Worchester. A local newspaper, referred to the Otis shovel as ‘a specimen of what the Irishmen call digging by stame’.

The writer obviously felt Isaiah’s prophecy – immortalized by Handel in the Messiah oratorio – was coming to pass, ‘For cutting through a sandhill this steam digging machine must make a great saving of labor. The hills are laid low, and the valleys made high’.

This shovel worked on the Western Railroad for some three years and it was during construction of a later extension of the line to Chester that, in 1839 at Westfield, William Otis died at the age of 26.

In 1841 one of the shovels was at work in Troy, New York, and later that year and during 1842 Otis shovels were operating at Brooklyn, New York, excavating and filling swampland to make the city park. Justification for the use of the steam shovel was given by members of the American Institute after visiting the work site,

They said, “the masses of unruly men collected on our public works will be disbursed by its use, and compelled to till the land, thereby making them good and quiet citizens”. (image a journalist writing THAT in modern times!)

It is likely that one or both machines were used later in the 1840s on the Atlantic Docks project, also in Brooklyn, as the shovels’ owner by then, Daniel Carmichael, was a contractor. Subsequent records of the use of the two Philadelphia built shovels are vague: it appears the last one was broken up during the early 1900s, following a record of one being overhauled and about 1893 at Omaha, Nebraska.

Excavators entered the world trade right from their inception. By early in 1842 one was at work in England near Brentwood, Essex, on the eastern counties Railway. John Duncan, who had been granted an English patent presumably under some agreement, was responsible for its introduction and John Braithwaite was entrusted with the construction and licensing of further machines for the UK and Europe. There is, though, no evidence of Otis machines being made outside North America. In 1845 one improved by J. B. Hyde was mounted on a scow and used as a dredge in England, and in the following year and Otis shovel was employed at Hull, Humberside, on excavating the Victoria Dock, but these reports may well refer to the original imported unit.

Representatives of Russian authorities saw the Otis shovel at work on the Western Railroad in 1839: the result was that the railway company’s then consulting engineer, Maj. George G. Whistler (father of the famous portrait painter) was appointed consultant for the construction of the St. Petersburg (Leningrad)-Moscow railway. The first of the four Otis shovels was shipped to Russia, via France, in 1842, with the others following in 1843

At least two descendents of John Otis, who emigrated from England in 1631, and settled at Hingham, Massachusetts, were destined to make significant inventions, although history books only give due acknowledgment to the one associated with the creation of the passenger lifts.

William S. Otis, however, born in 1813 as the son of the Postmaster at Pelham, Massachusetts, is no less worthy of fame. Williams’ family moved in either 1828 or 1829 to Philadelphia, Pennsylvania, where in 1833 he joined the contracting firm of Carmichael & Fairbanks of which the senior partner, Danielle Carmichael, was his brother-in-law and by the following year he was himself a partner.

When Carmichael, Fairbanks and Otis had a contract to work on the construction of the Boston and Providence Railroad (later the New York, New Haven and Hartford) in 1835, William Otis made his temporary home at Canton, Massachusetts. Here, not only did he meet and marry a local girl, but also – with the help of a local man, Charles Howe French, recently out of apprenticeship to a millwright – he designed and built the prototype of the world’s first successful, powered, dry land excavator. This, built in a machine shop near the Massapoag Brook, was probably based on the quarry derrick principle and is believed to have had a mast supported by cables, a luffing-type dipper arm and bucket hinged to a boom, a double drum hoisting engine, and boom swing achieved by men at the sides pulling on ropes. The machine was clearly not easily moved as the derrick and excavating equipment were not fixed to a readily mobile frame also carrying the engine.

This Canton-built prototype was later used by Charles French on construction of the Norwich and Worchester railroad; and was possibly the same machine, incorporated into a dredge designed by Hosea T. Stock, which Charles French and Daniel Carmichael operated as contractors widening the Welland Canal, Ontario, in the 1840s and 1850s.

William Otis returned to Philadelphia in 1836, intent on building an improved version of his excavator himself with parts made by local machine shops. In the event he entrusted the complete erection of seven machines to Garrett and Eastwick, builders are locomotives and stationary engines, with premises on 12th St. The first Philadelphia built Otis shovel was produced in 1837 and by the time the second emerged the firm’s name had become Eastwick and Harrison; Joseph Harrison Junior, the skilled foreman who is likely to have contributed much to perfecting mechanical details of the shovel’s design, had bought out Garrett’s interest.

Although William Otis had filed his original patent application on the 15th of June 1836, a fire in the patent office destroyed this and a second application dated 27th of October 1836 was allowed on 24th of February 1839 and numbered as 1089. In this new restored patent application for a ‘Crane excavator for excavating and removing earth’ the inventor did not make any claim to the mere using other scraper by means of a train, this having been done before.

The Otis shovel was the first excavator to break and remove material by employing a single bucket with power thrust for adjusting the radius of a cut above, and to a limited extent below, ground-level. It was self-propelled and exhibited the three basic digging features still present in excavators equipped as a shovels: these are hoist, crowd (or racking) and slew (or swing).

Philadelphia built Otis shovels had a wide timber frame supported on cast iron traveling wheels which ran on temporary rails; the frame carried the boiler, engine and gears as well as all the excavating equipment and had projections with screw jacks for added stability when working. A triangular timber boom was supported by a pivoted, tubular, cast iron center post with a semicircular slewing ring attached to its top.

Power for hoisting was taken by chain from a grooved drum, through the inside of the center post to pulleys on the post and boom and then down to the bucket (scraper). A shaft with bevel wheels at each end carried a power down from the post pulley to another shaft between the main lower braces of the boom which, with its appendages, was the key feature of the Otis shovel. A drum fitted to this shaft carry chains in reversed direction attached to opposite ends of the dipper arm: this device provided controlled thrust with the capability of absorbing shocks, to the arm and its bucket of around 1 1/4 yd.³ capacity.

Up to 180° of slew was achieved by means of a chain from another drum taken round the sloughing ring. At the rear of the machine, a vertical wood-burning boiler provided low-pressure steam to a single cylinder vertical engine, with an approximate a bore of 23 cm (9 inches) diameter and 30 cm (1 foot) stroke, fitted at its front; this resulted in units ranging from about 8 to 20 hp. Contemporary accounts indicate that an Otis shovel could do the work of between 60 and 120 men: it’s estimated output was around 100 yd.³ of material per hour.

Of the seven Philadelphia-built shovels only two remained in North America. There are suggestions that the first work undertaken by one of these was on the Baltimore and Ohio Railroad in Maryland, but the first incontrovertible use of a powered excavator was in 1838 at Springfield, Massachusetts when Carmichael, Fairbanks and Otis were building a link of the Western Railroad (later Boston and Albany) to Worchester. A local newspaper, referred to the Otis shovel as ‘a specimen of what the Irishmen call digging by stame’.

The writer obviously felt Isaiah’s prophecy – immortalized by Handel in the Messiah oratorio – was coming to pass, ‘For cutting through a sandhill this steam digging machine must make a great saving of labor. The hills are laid low, and the valleys made high’.

This shovel worked on the Western Railroad for some three years and it was during construction of a later extension of the line to Chester that, in 1839 at Westfield, William Otis died at the age of 26.

In 1841 one of the shovels was at work in Troy, New York, and later that year and during 1842 Otis shovels were operating at Brooklyn, New York, excavating and filling swampland to make the city park. Justification for the use of the steam shovel was given by members of the American Institute after visiting the work site,

They said, “the masses of unruly men collected on our public works will be disbursed by its use, and compelled to till the land, thereby making them good and quiet citizens”. (image a journalist writing THAT in modern times!)

It is likely that one or both machines were used later in the 1840s on the Atlantic Docks project, also in Brooklyn, as the shovels’ owner by then, Daniel Carmichael, was a contractor. Subsequent records of the use of the two Philadelphia built shovels are vague: it appears the last one was broken up during the early 1900s, following a record of one being overhauled and about 1893 at Omaha, Nebraska.

Excavators entered the world trade right from their inception. By early in 1842 one was at work in England near Brentwood, Essex, on the eastern counties Railway. John Duncan, who had been granted an English patent presumably under some agreement, was responsible for its introduction and John Braithwaite was entrusted with the construction and licensing of further machines for the UK and Europe. There is, though, no evidence of Otis machines being made outside North America. In 1845 one improved by J. B. Hyde was mounted on a scow and used as a dredge in England, and in the following year and Otis shovel was employed at Hull, Humberside, on excavating the Victoria Dock, but these reports may well refer to the original imported unit.

Representatives of Russian authorities saw the Otis shovel at work on the Western Railroad in 1839: the result was that the railway company’s then consulting engineer, Maj. George G. Whistler (father of the famous portrait painter) was appointed consultant for the construction of the St. Petersburg (Leningrad)-Moscow railway. The first of the four Otis shovels was shipped to Russia, via France, in 1842, with the others following in 1843

Some historians give credit to an American named Benjamin Holt for inventing the first "bulldozer" in 1904, and originally calling it a "caterpillar" or a crawler tractor. However, this would be misleading.

Benjamin Holt did not Build a Bulldozer

Expert, Deas Plant from the Gold Coast, Queensland, Australia commented that Benjamin Holt developed an endless chain tread for his steam traction engine at the end of 1904. At around the same time, the Hornsby company of England converted one of its wheeled steam traction engine to a tracklayer [crawler] format based on a patent granted to their chief engineer. Neither of these developments was a bulldozer, both were purely and simply track-laying traction engines. However, the Hornsby's version was closer to the bulldozers we know today in that it was steered by controlling power to each track instead of having a tiller wheel out in front of the tracks as Holt's machines did. Hornsby sold their patents to Benjamin Holt around 1913-14.

Benjamin Holt did not Build a Bulldozer

Expert, Deas Plant from the Gold Coast, Queensland, Australia commented that Benjamin Holt developed an endless chain tread for his steam traction engine at the end of 1904. At around the same time, the Hornsby company of England converted one of its wheeled steam traction engine to a tracklayer [crawler] format based on a patent granted to their chief engineer. Neither of these developments was a bulldozer, both were purely and simply track-laying traction engines. However, the Hornsby's version was closer to the bulldozers we know today in that it was steered by controlling power to each track instead of having a tiller wheel out in front of the tracks as Holt's machines did. Hornsby sold their patents to Benjamin Holt around 1913-14.

First Came the Bulldozer Blade

It is not certain who invented the first bulldozer, however, the bulldozer blade was in use before the invention of any tractor. It consisted of a frame with a blade at the front into which were harnessed two mules. The mules would push the blade into a heap of dirt dumped by a cart and spread the dirt or push it over a bank to fill a hole or gully. The fun part came when you wanted the mules to back up for the next push.

Definition of a Bulldozer

The term bulldozer technically refers only to a shovel-like blade, over the years people have come to associate the term bulldozer to the entire vehicle both blade and crawler tractor combined.

Deas Plant added that "There is also some debate about who first fitted a bulldozer blade to a track-laying tractor, perhaps the La Plante-Choate company, one of the early manufacturers of bulldozer blades."

Again, there are various claimants for the title of first to fit a power control to one of these bulldozer blades with Robert Gilmour Le Tourneau probably being the leading contender.

The Caterpillar Tractor Company

The name caterpillar was coined by a photographer working for Benjamin Holt who was taking photos of one of Holt's track-laying or crawler tractors. Looking at the machine's upside-down image through his camera lens, he commented that the top of the track undulating over its carrier rollers looked like a caterpillar. Benjamin Holt liked the comparison and adopted it as the name for his track-laying system. He was using it for some years before the formation of the Caterpillar Tractor Company.

The Caterpillar Tractor Company was formed by the merger of the Holt company and their major competitor, the C. L. Best Gas Tractor Co., in August, 1925.

What Do Bulldozers and Bulls Have in Common?

It appears that the word bulldozer came from the habit of stronger bulls pushing their lesser rivals backwards in not-so-serious contests of strength outside of the mating season. These contests take on a more serious note during the mating season.

According to "Bulldozers" written by Sam Sargent and Michael Alves: "Around 1880, the common usage of 'bull-dose' in the United States meant administering a large and efficient dose of any sort of medicine or punishment. If you 'bull-dosed' someone, you gave him a severe whipping or coerced or intimidated him in some other way, such as by holding a gun to his head... In 1886, with a slight variation in spelling, a 'bulldozer' had come to mean both a large-caliber pistol and the person who wielded it... By the late 1800s, 'bulldozing' came to mean using brawny force to push over, or through, any obstacle."

The technology on today's boom trucks is so sophisticated that it is hard to believe how long ago cranes were actually invented.

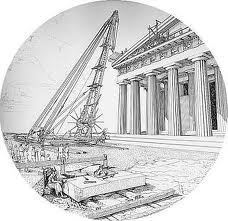

In the historical record, lifting devices for water first appeared in Ramses' Egypt. While scholars have concluded that some kind of crane must have been used to build the pyramids, it was in ancient Greece that signs of crane technology were first seen.

The first evidence of a crane came in buildings constructed in 6th century BC. The blocks used in construction had holes that indicated the presence of a lifting device. Because the holes were above the center of gravity of the block or in pairs an equal distance from a point over the center of gravity, archaeologists believe that a crane was used to lift them into place. They also believe that the crane used a ramp for vertical movement - the same method the ancient Egyptians very likely used.

In the historical record, lifting devices for water first appeared in Ramses' Egypt. While scholars have concluded that some kind of crane must have been used to build the pyramids, it was in ancient Greece that signs of crane technology were first seen.

The first evidence of a crane came in buildings constructed in 6th century BC. The blocks used in construction had holes that indicated the presence of a lifting device. Because the holes were above the center of gravity of the block or in pairs an equal distance from a point over the center of gravity, archaeologists believe that a crane was used to lift them into place. They also believe that the crane used a ramp for vertical movement - the same method the ancient Egyptians very likely used.

The Greeks later developed a simple but effective winch and pulley system that replaced the ramp and enabled them to lift heavier blocks. It is believed that cranes like this were used to erect buildings like the Parthenon.

From ancient Greece, the crane's history takes us to ancient Rome. The Romans took the Greek crane and improved it, giving themselves the ability to build huge structures. Early Roman cranes had a three-pulley system that, it is believed, enabled them to lift up to 150 kg. From there, the Romans extended the size and lifting capacity of their cranes.

The early three-pulley crane gave way to a five-pulley crane. This innovation was soon replaced by a treadwheel, which took the place of the winch. With the treadwheel's larger diameter, load weights increased to 6,000 kg. As a Wikipedia entry notes, this meant that the lifting capacity of an ancient Roman crane - where 2 men could lift 6,000 kg - was 60 times higher than the ramp system used in Egypt, which required about 50 people to move a 2,500 kg stone block.

The Romans developed crane technology even more, through use of a lifting tower with four masts, surrounded by capstans which were turned by people or animals to tighten the ropes and lift the load. This crane allowed them to lift blocks of several tons to heights as high as 34 metres.

Shifting to the Middle Ages, crane technology finds its way to the harbour. Cities in Belgium and Germany used harbour cranes as early as the mid-1200s. Cranes from this era used the treadwheel design favoured in ancient Rome.

The technology changed little until the 1800s when crane manufacturers began using cast iron and wire rope. These innovations made the crane stronger, more durable, and more capable of lifting heavy loads.

After a few more innovations, like the addition of arch-shaped jibs, the first mobile crane was developed. Mounted on train cars, these cranes moved along short rail lines constructed specifically for each project in which they were employed. By the 1920s cranes were mounted on crawler tracks to become the crawler cranes we are familiar with today.

The next major innovation came in World War II with the advent of hydraulic technology, which was incorporated into cranes by a Swedish ski manufacturer. In the 1940s, Eric Sundin discovered a way to convert the power in a truck's engine into the power needed to generate a lifting motion. In 1944 he founded Hydrauliska Industri AB Co. (now known as HIAB). By 1947, the company had produced the world's first hydraulic truck mounted crane.

Which brings us to today, when cranes like those built by HIAB can lift 100 tonne-meters and reach as far as 28 m.

A very impressive history, wouldn't you say?